Digital Workflow In Implantology

In Vitadent clinic dental implants are placed using innovative digital workflow which allows us to deliver the best possible treatment to patients. In implantology, digital workflow has several advantages, such as precise planning and simplified surgical approach, which result in a faster and more predictable surgery, reduced risk of complications and greater comfort for patients.

The use of digital technologies for the optimisation of implant treatment is used throughout the whole process, such as for diagnosis, planning, placement and restoration of implants. Offering so many benefits to both patients and clinicians, this technology is quickly becoming the standard of care.

Digital Implantology Step-by-step

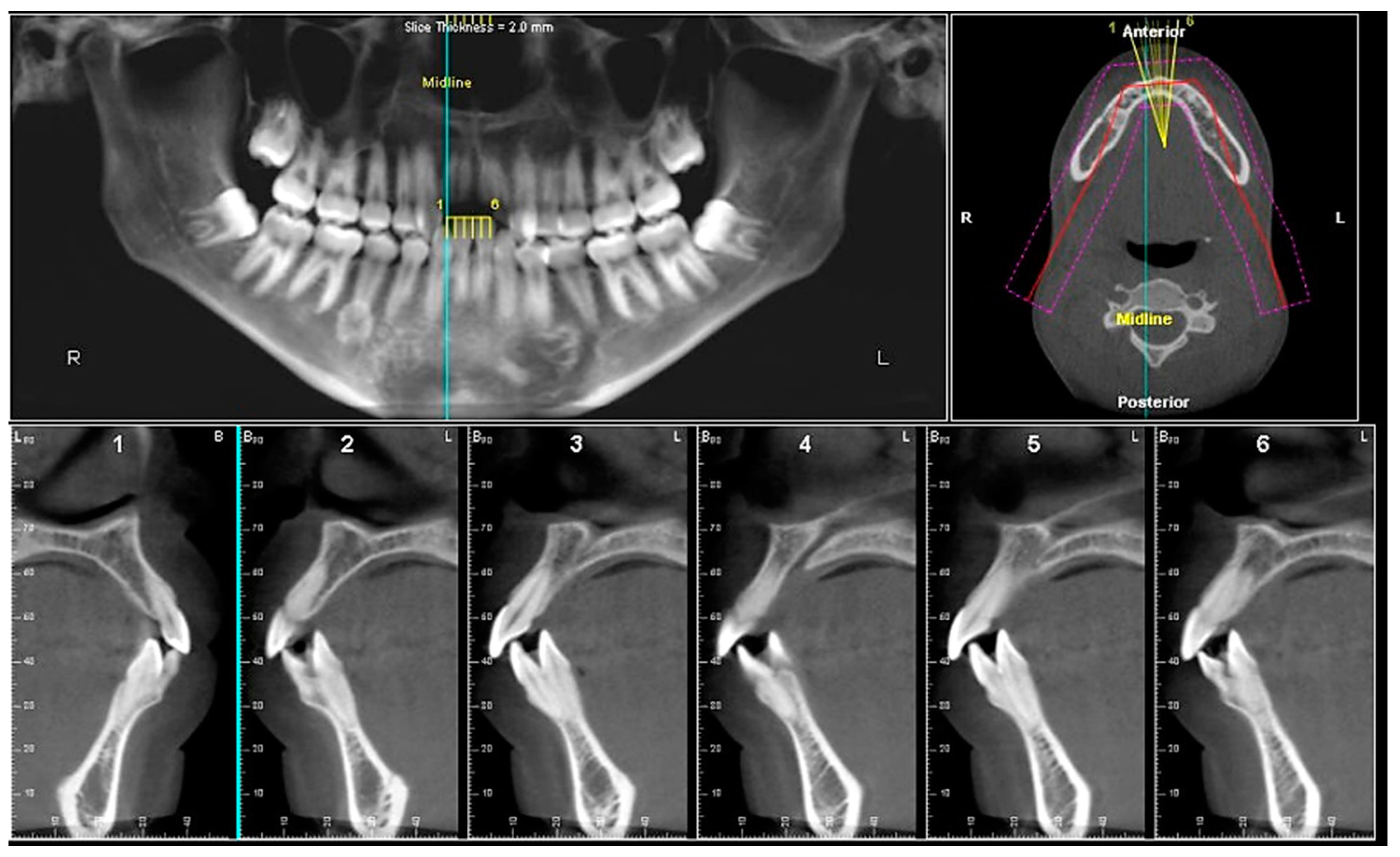

Implant planning begins with performing Dental cone beam computed tomography (CBCT). This type of CT scanner uses a special type of technology to generate three dimensional (3-D) images of dental structures, soft tissues, nerve paths and bone in the craniofacial region in a single scan, providing the full diagnostic information and allowing for more precise treatment planning.

The next step – digital diagnostic impressions are taken from your teeth. It’s a fast a comfortable procedure performed with the intraoral scanner; no spoons and impression materials needed.

Then CBCT data is merged with the intraoral scan of the patient’s teeth and gingiva in a computer-guided 3D implant planning software, allowing for visualization that aids in diagnosis and treatment planning.

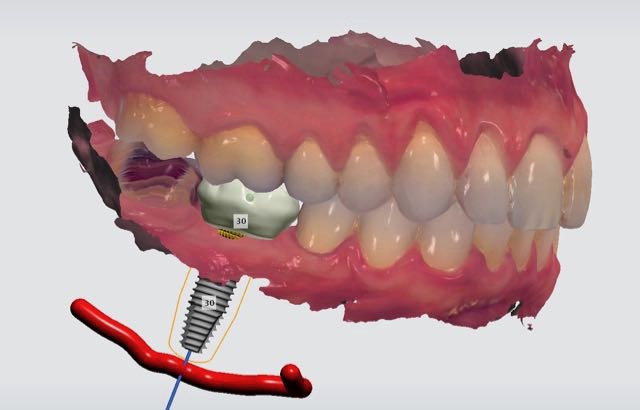

In addition to allowing practitioners to accurately assess bone volume, bone density and restorative space, the location of the prosthesis can be merged from the digital wax-up and preoperative scan for prosthetically driven implant planning. Designing the crown in the ideal position and alignment with the neighboring and opposed teeth, we will automatically obtain the best implant position within the bone. Furthermore, critical anatomic landmarks — such as nerves and sinuses can be identified and avoided. The software allows clinicians to visualize the prosthetic plan before the surgery. When planning multiple implants, each can be instantly paralleled using the software, which greatly simplifies restoration of complicated cases.

Once the treatment plan is accepted, the surgical guide will be designed. It replicates the exact surfaces of the patient’s intraoral setting and assists the surgeon to drill implants into the bone with optimal accuracy. Surgical guides are fabricated using 3D-printer.

The benefits of this technology to the clinician and patient are significant compared to freehand surgery:

- greater precision in implant placement which results in increased restorative simplicity and excellent outcome

- faster procedure, increased patient comfort

- reduced probability of having a positional error, eliminating the human factor

- the procedure can be done without a gum incision, therefore patients benefit by experiencing significantly less intraoperative and postoperative complications, including pain, swelling and hematoma.

- in many cases bone augmentation procedures may be avoided or reduced due to the accuracy that digital planning provides

Digital technology is applied in the restorative phase of implant dentistry as well. Once the implant is placed and integrated in the bone, the exact position will be registered and transferred to a digital model. All of the necessary information can be captured with intraoral scanners. Permanent crown/prosthesis will be designed and milled by dental technician using CAD-CAM technology. Furthermore, digitally designed and milled provisional restorations can be fabricated before the surgical procedure to provide the patient with immediate temporary solution if necessary.